Acquire Reliable Bobcat Aftermarket Parts for Boosted Machinery Effectiveness

Acquire Reliable Bobcat Aftermarket Parts for Boosted Machinery Effectiveness

Blog Article

Optimizing Efficiency: The Duty of Aftermarket Components in Machinery and Heavy Equipment

In the world of machinery and heavy equipment, the mission for optimum effectiveness is a perpetual quest. One key facet that often goes unnoticed but holds tremendous capacity is the use of aftermarket parts. These elements, while sometimes overlooked, play a crucial function in the efficiency and long life of equipment. From cost-saving steps to boosting functional efficiency, aftermarket parts have confirmed to be instrumental in maximizing efficiency in various sectors. As we discover the intricacies of this subject, a deeper understanding of the advantages and effects of aftermarket parts will unquestionably clarify their important duty in the realm of machinery and hefty equipment.

Benefits of Making Use Of Aftermarket Parts

Making use of aftermarket parts in machinery and heavy equipment can lead to cost financial savings and enhanced operational performance. One of the primary advantages of making use of aftermarket components is the possibility for significant price reductions compared to purchasing original equipment maker (OEM) components.

Additionally, aftermarket parts can offer a wider series of options and schedule than OEM parts. With countless suppliers producing aftermarket parts, consumers have the adaptability to select from a selection of brand names and requirements to best suit their specific needs. This selection not only supplies better customization chances however also enables faster accessibility to components, lowering downtime and boosting total functional performance. By leveraging the advantages of aftermarket components, companies can achieve cost-efficient maintenance services while improving the performance and longevity of their equipment and hefty equipment.

Cost-Saving Approaches

Given the monetary advantages related to aftermarket parts, checking out reliable cost-saving strategies comes to be essential for businesses looking for to maximize their functional effectiveness and maintenance spending plans. One essential technique is to perform thorough research to recognize respectable aftermarket components vendors that provide top notch products at affordable costs. By partnering with reputable vendors, services can safeguard affordable solutions without compromising on the efficiency or longevity of their machinery and hefty devices.

An additional cost-saving approach is to implement positive maintenance practices that focus on the prompt substitute of components prior to they fail. By investing in preventative maintenance and replacing parts with aftermarket parts before they get to completion of their life span, companies can avoid costly downtime, emergency repair work, and possible damage to other components of the equipment.

Additionally, leveraging mass buying agreements with aftermarket parts vendors can lead to considerable price financial savings for services with huge fleets of equipment and devices. By bargaining desirable rates terms based on quantity acquisitions, firms can decrease their total upkeep expenses while ensuring they have a trusted supply of aftermarket components to sustain their procedures.

Enhancing Tools Performance

Enhancing tools efficiency needs a critical approach that encompasses optimizing maintenance schedules and making use of innovative technical services. Applying positive upkeep routines, including regular examinations, lubrication, and components replacements, can protect against unforeseen failures and prolong the life expectancy of the equipment.

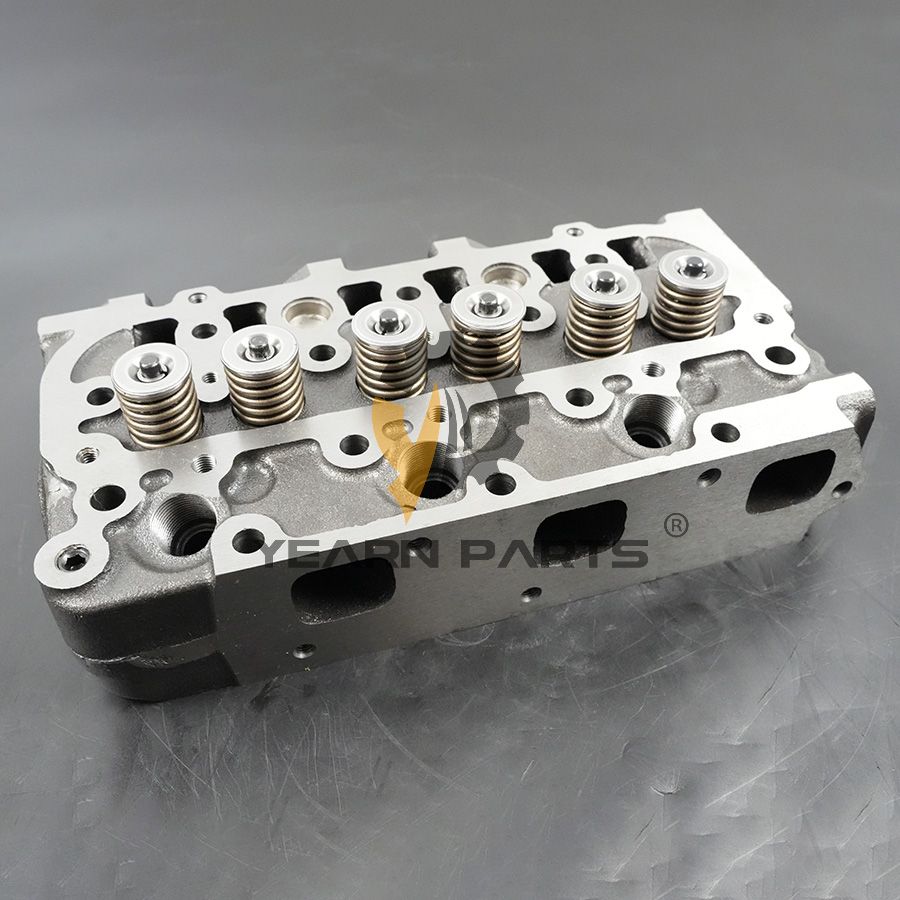

In addition, purchasing aftermarket components that are particularly made for improving equipment performance can additionally play a substantial function. Upgrading parts like filters, belts, and hydraulic systems with high-quality aftermarket components can improve general efficiency and efficiency. These components are commonly engineered to fulfill or exceed OEM requirements, using an affordable means to boost tools capabilities without endangering on quality. By combining tactical maintenance exercise with cutting-edge technological options and aftermarket parts, businesses can enhance devices efficiency and optimize their operational efficiency.

Reducing Downtime

One effective method for reducing downtime is the usage of high-quality aftermarket components. read this post here These components are developed to surpass the efficiency or fulfill of initial devices supplier (OEM) components, guaranteeing reliable operation and minimizing the threat of unforeseen malfunctions.

Normal maintenance routines that include the evaluation and replacement of used elements with aftermarket parts can assist prevent devices failures and lengthen the lifespan of equipment (Bobcat Aftermarket Parts). By proactively addressing potential concerns, organizations can lessen the regularity and period of downtime, inevitably maximizing performance and success

Furthermore, having a stock of frequently needed aftermarket parts on hand can speed up fixing procedures and decrease tools downtime. Quick access to these parts enables upkeep teams to swiftly resolve issues as they arise, reducing interruptions to procedures and maintaining projects on the right track. Generally, focusing on making use of aftermarket components can play a crucial role in reducing downtime and maximizing equipment performance over time.

Boosting Equipment Life Expectancy

Expanding the operational long life of equipment and hefty equipment is extremely important for services looking for to maximize investments and maintain consistent productivity degrees. Increasing the life-span of tools entails positive upkeep strategies, prompt repairs, and making use of high-grade aftermarket components. By carrying out a detailed upkeep schedule that consists of normal assessments, lubrication, and part substitutes when necessary, businesses can stop premature wear and breakdowns that can substantially reduce devices life expectancy.

Making use of aftermarket components specifically designed for hefty equipment can additionally contribute to prolonging equipment lifespan. These components are typically more cost-effective than original equipment supplier (OEM) components without jeopardizing on high quality. Aftermarket components are manufactured to satisfy market standards and can supply equivalent performance and durability to OEM elements.

Furthermore, drivers and maintenance personnel play an essential function in extending devices life expectancy by complying with correct operating treatments, conducting routine checks, and immediately addressing any type of concerns that develop. By prioritizing devices durability through proactive upkeep, the demand for premature substitutes is minimized, inevitably saving organizations time published here and money while ensuring operational performance.

Final Thought

Finally, aftermarket components play a crucial function in making the most of effectiveness for equipment and heavy devices. By utilizing these parts, organizations can gain from cost-saving strategies, improved tools performance, decreased downtime, and increased equipment lifespan. Overall, using aftermarket components provides a functional solution for maximizing the performance and performance of equipment and hefty tools operations.

One of the primary advantages of using aftermarket components is the potential for significant price decreases compared to purchasing initial devices maker (OEM) components.Moreover, aftermarket parts can provide a more comprehensive variety of choices and accessibility than OEM parts - Bobcat Aftermarket Parts. These parts are made to surpass the efficiency or satisfy of original tools manufacturer (OEM) parts, making sure trustworthy operation and minimizing the threat of unanticipated break downs

Report this page